The Power Quality Problems Costing Australian Industry Thousands

Power quality issues don’t just trip breakers – they destroy equipment, halt production, and rack up costs in downtime and repairs. Electrical contractors and facility maintenance teams across Australia face the same challenge: intermittent faults that are impossible to catch without the right monitoring equipment.

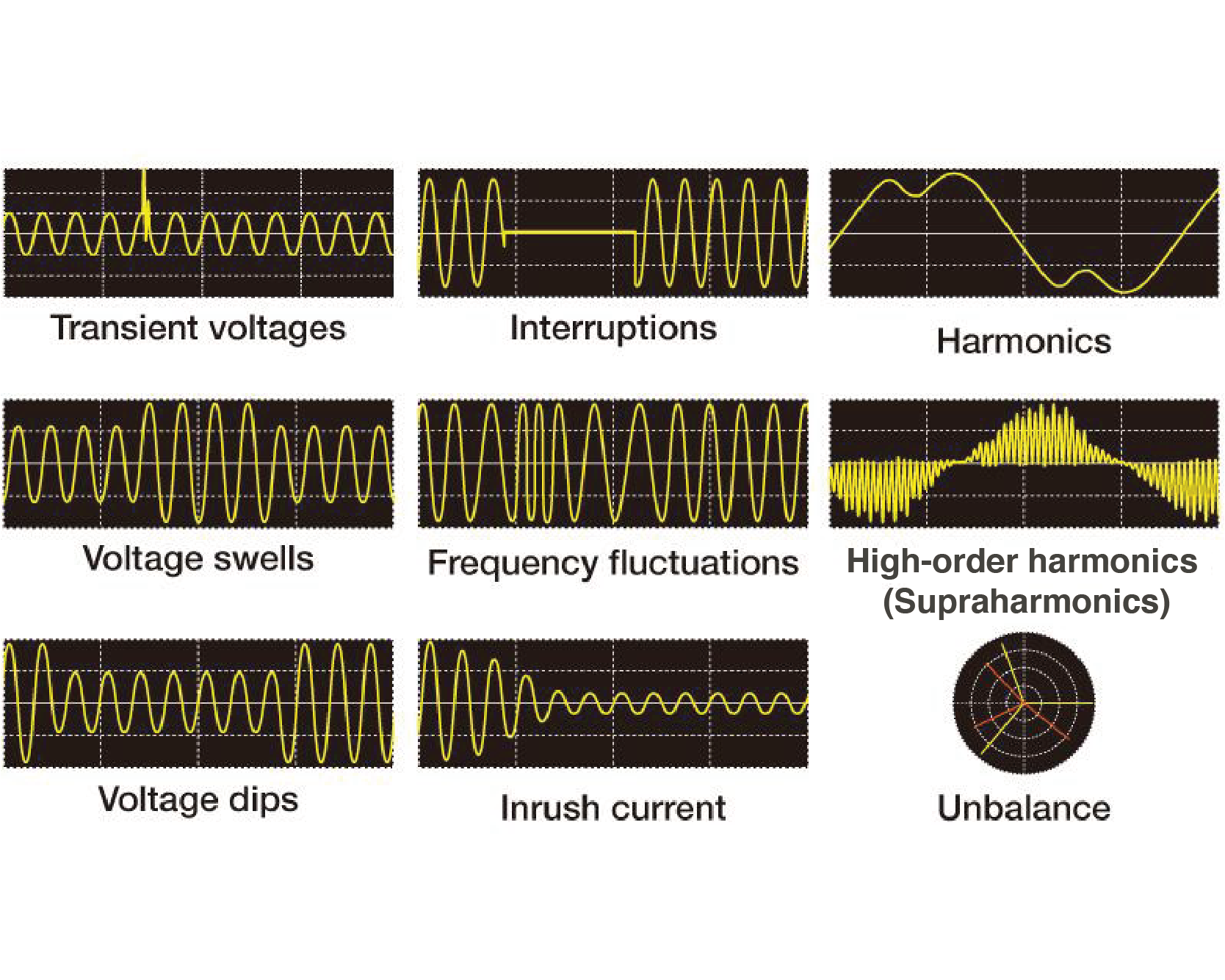

Voltage dips from switching operations damage sensitive electronics. Harmonic distortion from variable speed drives overheats transformers. Transient spikes from lightning or switching events destroy control systems. Without proper power quality analysis, you’re troubleshooting blind – replacing components without understanding the root cause.

The stakes are even higher when compliance is on the line. Whether you’re commissioning solar installations, certifying industrial systems, or verifying power supply quality for critical infrastructure, you need measurement data that stands up to engineering scrutiny and regulatory standards.

How the Hioki PQ3198 Solves Your Power Quality Challenges

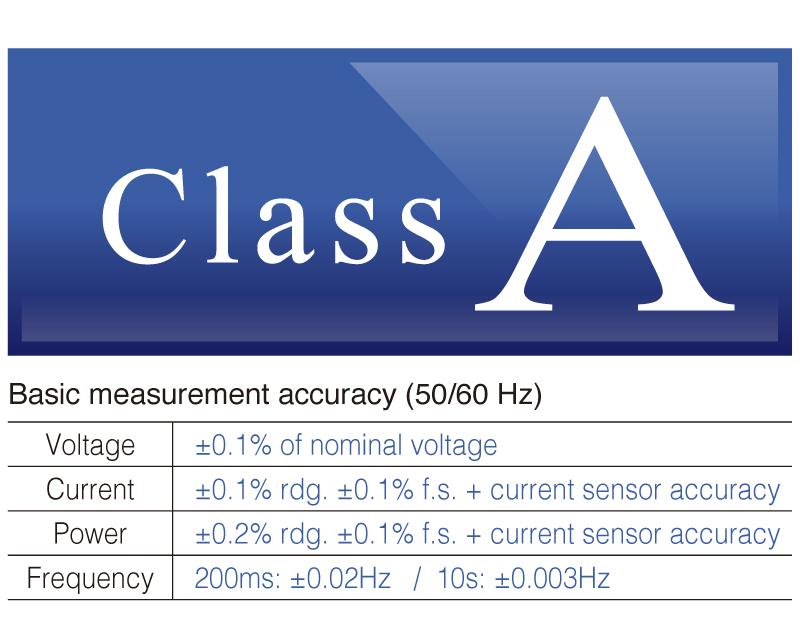

The Hioki PQ3198 Power Quality Analyzer is built for professionals who need accurate answers, not guesswork. This three-phase analyzer combines comprehensive monitoring capabilities with genuine compliance certification – meeting IEC 61000-4-30 Edition 3 Class A standards for power quality measurement.

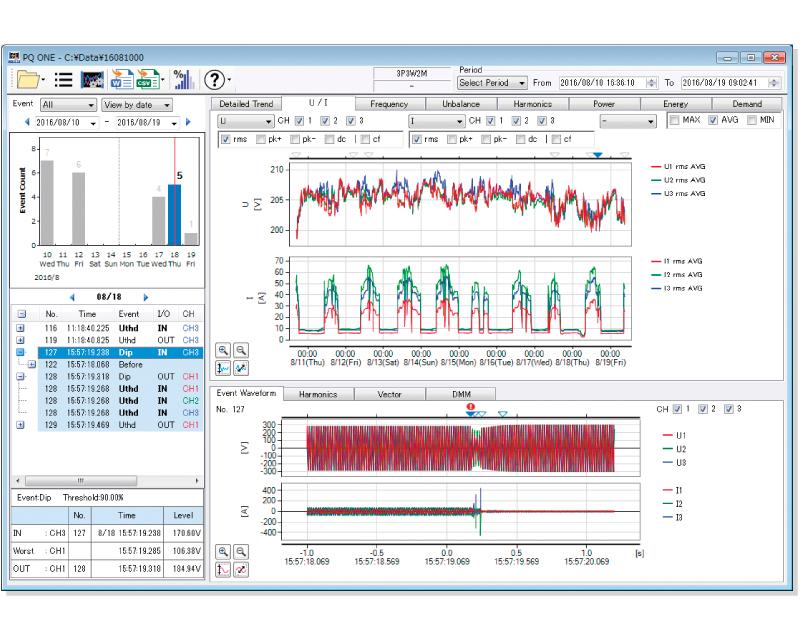

Here’s what sets this analyzer apart: it captures everything simultaneously. While recording trend data for long-term monitoring, it’s simultaneously watching for voltage swells, dips, interruptions, harmonics, flicker, and transient spikes up to 6000V. When an anomaly occurs, it captures the waveform with 2 MHz sampling – giving you the forensic detail needed to pinpoint causes.

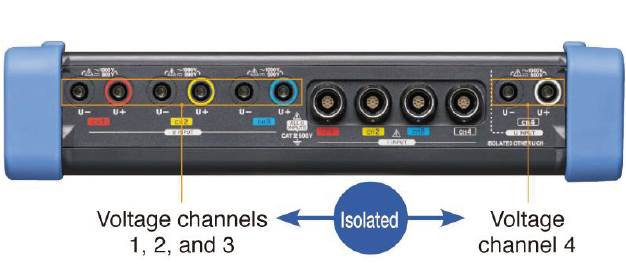

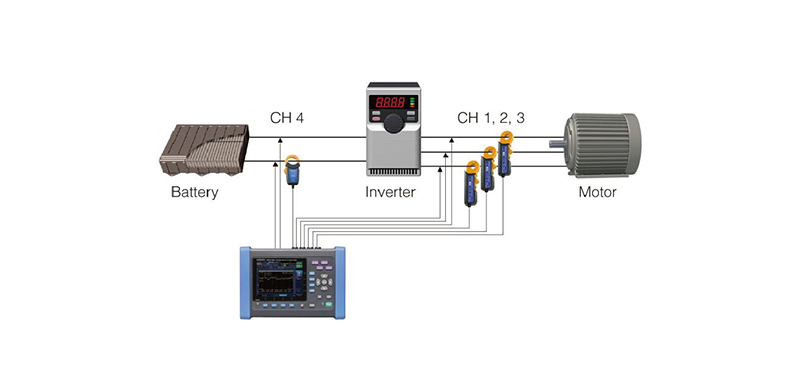

The PQ3198’s dual-circuit capability is particularly valuable for Australian solar and EV infrastructure work. Measure both the AC input and DC output of an EV rapid charger simultaneously, or monitor inverter efficiency across primary and secondary circuits – all from a single instrument. The isolated fourth channel eliminates the need for multiple analyzers on complex jobs.

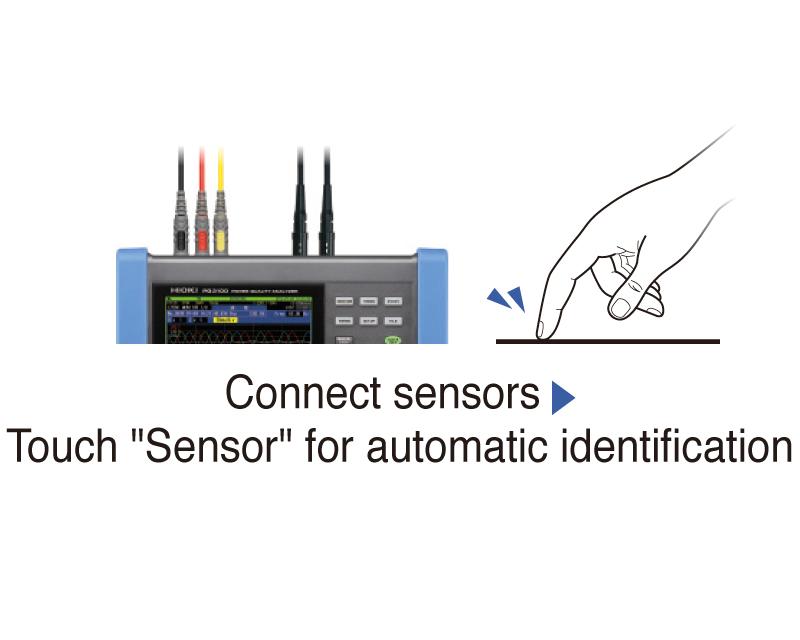

What really makes this analyzer trade-ready is how Hioki handles current sensing. The PQ3198 powers sensors directly – no external power supplies cluttering your setup. Connect any Hioki current sensor from 500mA to 6000A, and the analyzer automatically detects the sensor type and range. The built-in wiring check verifies your connections before you start recording, catching setup errors before they cost you time.

Key Benefits & Professional Applications

Compliance-Ready Certification You Can Trust

The PQ3198’s IEC 61000-4-30 Class A certification isn’t just a label – it’s your assurance that measurement data meets international standards for power quality assessment. This matters when you’re producing reports for engineers, submitting compliance documentation, or defending findings against warranty claims. The analyzer’s ±0.1% voltage accuracy and gapless continuous recording mean your data holds up under scrutiny.

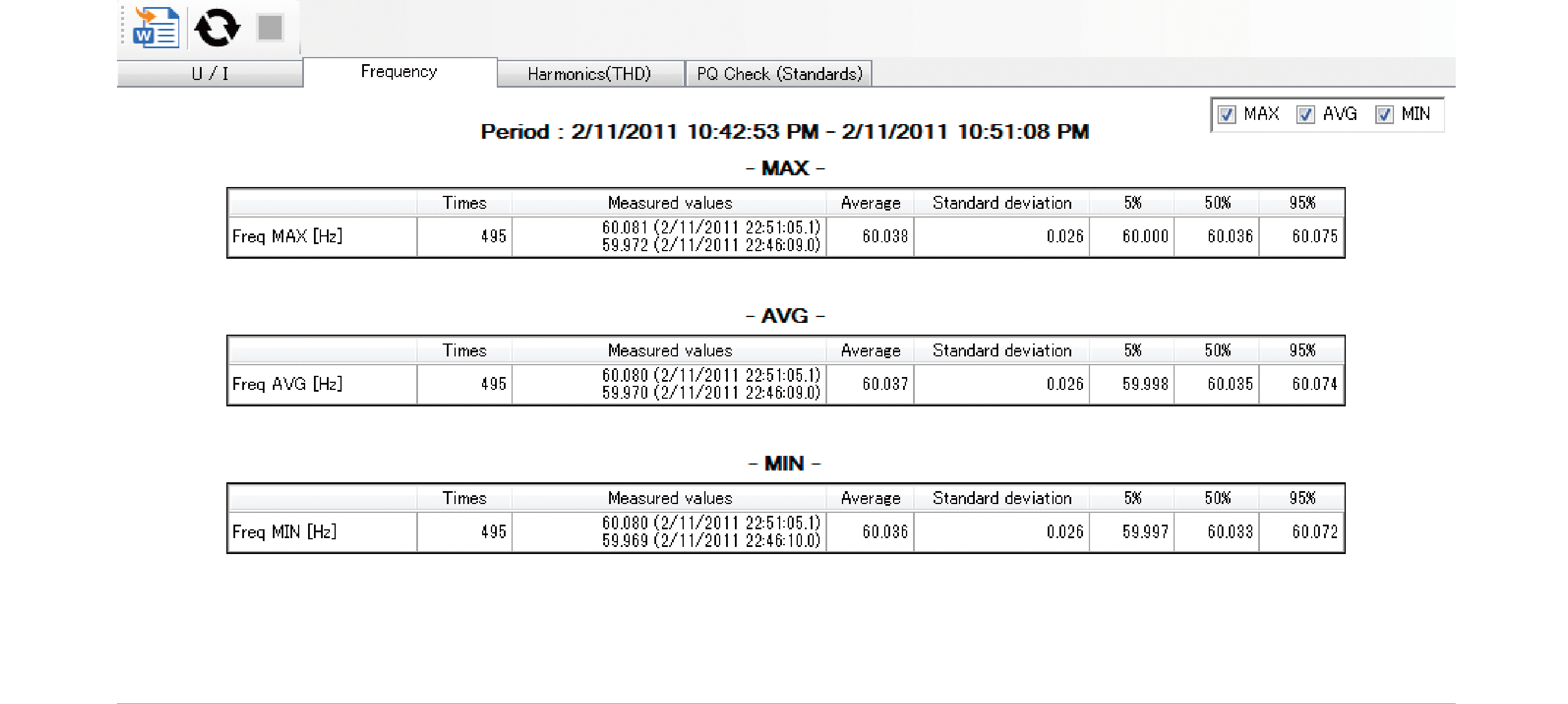

For Australian solar installers, this certification is essential for grid connection approvals. The PQ3198 also evaluates power supply quality against EN 50160 standards using the included PQ ONE software, automatically generating compliance reports that document voltage characteristics, frequency variations, and harmonic limits.

Capture the Events Others Miss

Transient voltage spikes lasting just microseconds can destroy equipment – but only if you can measure them. The PQ3198 captures transient voltages up to 6000V peak with 0.5 μs resolution, recording the fast-acting events that standard power meters simply can’t see. This capability is critical when investigating lightning damage, breaker operations, or unexplained equipment failures in industrial facilities.

The analyzer stores up to 9999 power quality events with complete waveform data, building a comprehensive history of power supply disturbances over weeks or months. Each event includes context – trend data showing what was happening before, during, and after the anomaly. This forensic detail transforms troubleshooting from educated guessing into data-driven problem solving.

High-Order Harmonic Analysis for Modern Power Systems

Today’s variable frequency drives, switch-mode power supplies, and renewable energy systems generate harmonic distortion well beyond the traditional 50th order limit. The PQ3198 measures supraharmonics from 2 kHz to 80 kHz – capturing the high-frequency noise that overheats motors, trips protection devices, and interferes with communications systems.

This extended frequency range is particularly valuable for analyzing solar inverters and EV charging infrastructure, where switching frequencies create harmonic content above 20 kHz. The analyzer also calculates K-Factor for transformer derating – giving facility managers the data needed to prevent transformer failures from harmonic overload.

Two-Circuit Measurement for Complex Systems

Most power quality work involves more than simple three-phase monitoring. The PQ3198’s isolated fourth voltage channel enables simultaneous measurement of two separate circuits – measuring both input and output of inverters, UPS systems, or transformers without needing multiple instruments.

For solar installers, this means verifying inverter efficiency while monitoring grid connection quality from a single setup. For EV infrastructure work, measure the AC supply quality and DC output characteristics of rapid chargers in one test session. The analyzer calculates efficiency between circuits automatically, documenting system performance for commissioning reports.

Simple Setup, Professional Results

Hioki understands that time on site costs money. The PQ3198’s preset configurations eliminate complicated parameter setup – just select your application (general monitoring, EN 50160 compliance, solar PV, or inverter measurement) and the analyzer configures recording parameters automatically.

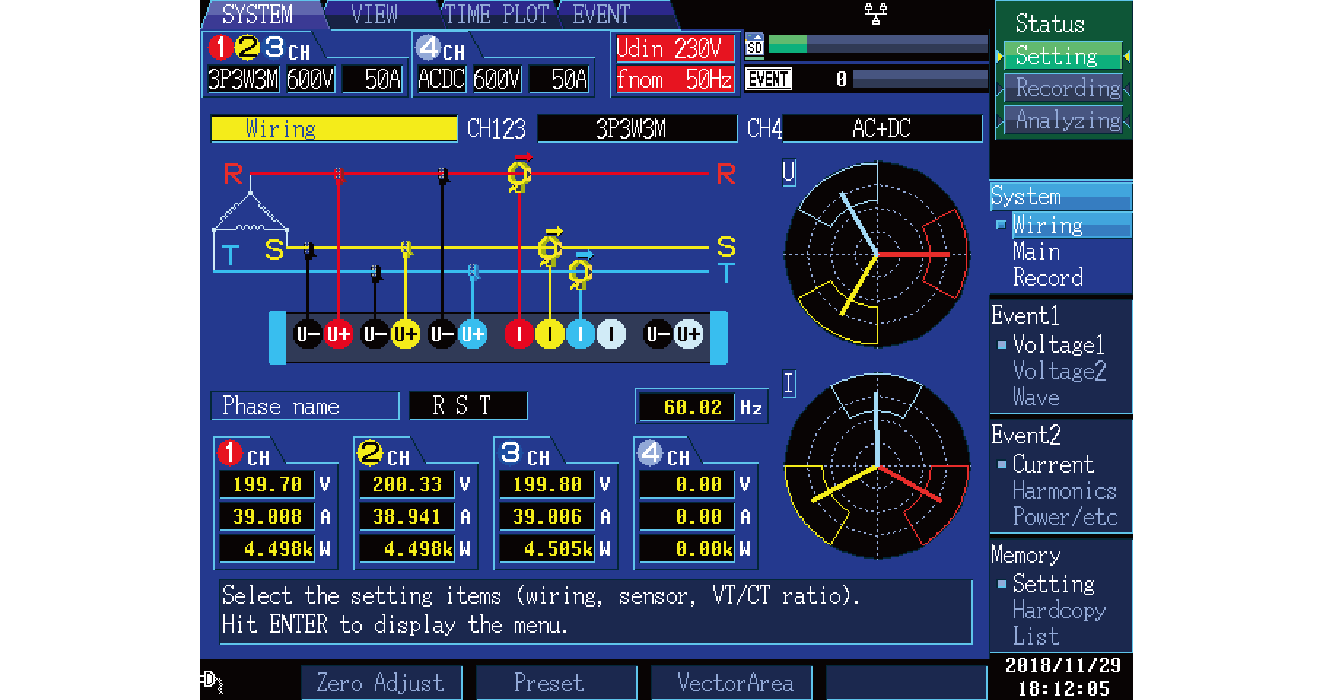

The wiring guide displays connection diagrams for single-phase, three-phase, and dual-circuit applications directly on the 6.5-inch color screen. Once connected, the automatic wiring check verifies your setup, identifying reversed phases or missing connections before you start recording. This built-in verification catches the setup errors that otherwise waste hours of measurement time.

Long-Term Monitoring Without Gaps

Power quality issues don’t run on your schedule. The PQ3198 records continuously for up to one year with gapless data – no missed samples, no time gaps in trend data. This continuous recording capability is essential for capturing intermittent problems that occur weekly or monthly rather than daily.

Battery operation extends recording beyond mains power availability, running for up to 180 minutes on the included rechargeable pack. For permanent monitoring installations, the optional waterproof enclosure (IP65 rated) enables outdoor deployment in harsh Australian conditions.

Technical Specifications

| Specification | Value | What This Means For You |

|---|---|---|

| Measurement Lines | Single-phase (2/3-wire), Three-phase (3/4-wire) plus isolated 4th channel | Handle any configuration from residential single-phase to industrial three-phase systems plus simultaneous secondary circuit |

| Voltage Range | 600 V rms measurement, 6000 V peak transient capture | Safely measure standard mains circuits while capturing lightning-induced transients and switching spikes |

| Current Range | 500 mA to 6000 A AC (sensor dependent) | From control circuit currents to main switchboard feeders – one analyzer covers all applications |

| Voltage Accuracy | ±0.1% of nominal voltage | Precision suitable for compliance testing and engineering analysis |

| Current Accuracy | ±0.1% rdg. ±0.1% f.s. (plus sensor accuracy) | Laboratory-grade measurement accuracy in a portable instrument |

| Power Accuracy | ±0.2% rdg. ±0.1% f.s. (plus sensor accuracy) | Reliable power and energy calculations for efficiency analysis |

| Compliance Standard | IEC 61000-4-30 Ed. 3 Class A | International standard for power quality measurement – results accepted worldwide |

| Harmonic Analysis | 0th to 50th order, plus 2 kHz to 80 kHz supraharmonics | Complete harmonic picture including modern high-frequency distortion from inverters and VFDs |

| Transient Capture | 2 MHz sampling (0.5 μs resolution) | Catch fast-acting voltage spikes that destroy equipment before they disappear from view |

| Recording Capacity | 9999 events, up to 1 year trend data | Long-term monitoring for intermittent problems with comprehensive event storage |

| Frequency Range | 40 to 70 Hz fundamental | Standard 50 Hz power plus 400 Hz aircraft/marine systems and variable frequency applications |

| Display | 6.5-inch color TFT (640 × 480 pixels) | Clear on-site viewing of waveforms and trend data in any lighting conditions |

| Power Supply | AC adapter (100-240V) or rechargeable battery pack | Mains or battery operation for flexibility across installations |

| Battery Runtime | 180 minutes continuous | Sufficient for mobile troubleshooting and areas without available mains power |

| Data Storage | SD/SDHC memory card | Industry-standard removable storage for easy data transfer |

| Communication | LAN (HTTP/FTP server), USB 2.0 | Remote monitoring, data download, and integration with facility monitoring systems |

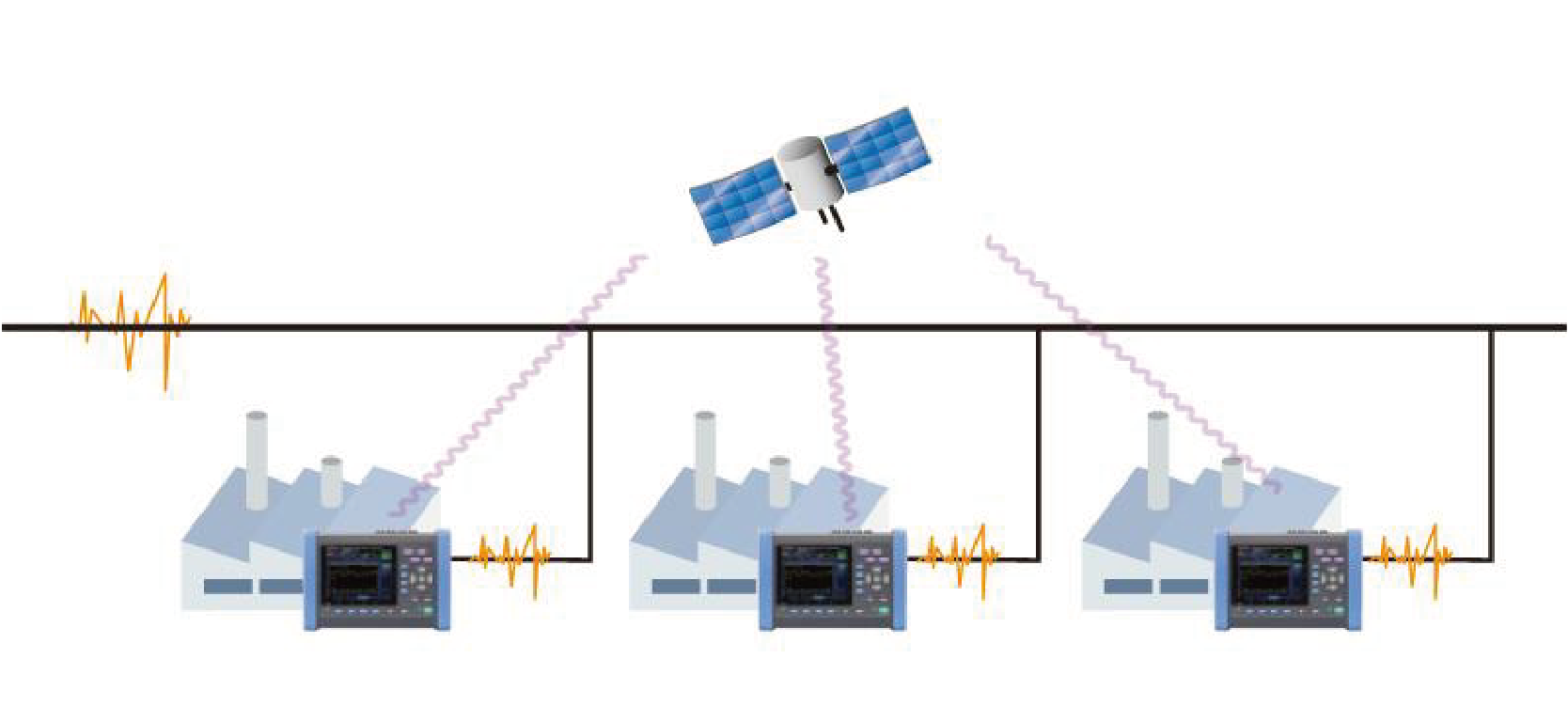

| GPS Synchronization | Optional GPS BOX (PW9005) | Synchronize multiple analyzers for investigating power quality issues across distributed locations |

| Dimensions | 300mm W × 211mm H × 68mm D | Portable size that doesn’t compromise screen size or measurement capability |

| Weight | 2.6 kg (with battery) | Light enough for extended field use, robust enough for industrial environments |

| Software | PQ ONE analysis and reporting (included) | Professional report generation with EN 50160 and IEEE 519 compliance evaluation |

Real-World Applications Across Australian Industries

Solar Installation Commissioning & Troubleshooting

Grid-connected solar systems require power quality verification for network approval and warranty compliance. The PQ3198 documents inverter output characteristics, harmonic content, and voltage regulation – generating the compliance reports that network operators require for connection approvals.

When solar installations experience unexplained shutdowns or grid export limiting, the PQ3198’s long-term monitoring identifies the cause. Capture the exact conditions triggering anti-islanding protection or overvoltage shutdowns, then use the waveform data to determine whether the issue lies with the inverter, transformer, or network supply.

Industrial Equipment Reliability & Maintenance

Manufacturing facilities lose thousands per hour when equipment fails unexpectedly. The PQ3198 helps maintenance teams move from reactive repairs to predictive maintenance – identifying power quality issues before they cause equipment damage.

Install the analyzer on critical motor control centers or process equipment, then review the recorded events to identify patterns. Voltage dips from crane operations, harmonic distortion from VFDs, or transient spikes from capacitor switching – whatever’s stressing your equipment, the PQ3198 captures the evidence needed to implement solutions.

EV Charging Infrastructure Certification

Electric vehicle rapid chargers draw significant power while maintaining strict quality requirements for the DC output feeding vehicles. The PQ3198’s dual-circuit capability verifies both AC supply quality and DC output characteristics simultaneously – documenting charger performance for commissioning and ongoing compliance.

This dual measurement capability also calculates overall charger efficiency, providing the data required for energy management reporting and utility demand response programs.

Data Center & Critical Infrastructure Monitoring

Data centers and critical facilities require continuous power quality assurance. Deploy the PQ3198 on UPS inputs and outputs to verify that backup power systems maintain quality during grid disturbances. The analyzer’s EN 50160 compliance checking automates the ongoing verification that power supply quality meets the standards required for sensitive IT equipment.

The optional GPS synchronization enables coordinated monitoring across multiple locations – capturing simultaneous events that affect distributed infrastructure and identifying whether power quality issues originate upstream or within specific facilities.

Building Services & Switchboard Testing

Electrical contractors troubleshooting lighting flicker, unexplained circuit breaker trips, or overheating transformers need forensic-quality power data. The PQ3198 documents the power quality characteristics that standard testing equipment can’t measure – voltage unbalance, harmonic distortion, neutral current, and flicker severity.

The analyzer’s preset configurations and automatic wiring verification mean even complex three-phase measurements are set up correctly first time. Generate professional reports directly from the included PQ ONE software – providing clients with clear documentation of findings and recommended solutions.

Why Choose Test Equipment Australia for Your Hioki PQ3198

Genuine Hioki Partnership & Local Support

We’re an authorized Hioki distributor, supplying genuine equipment backed by Hioki’s international warranty. Unlike gray imports, your PQ3198 comes with full Australian support, calibration services, and firmware updates. When you need technical guidance on applications or measurement setup, you’re talking to engineers who understand both the equipment and Australian power systems.

Calibration Services You Can Trust

Power quality measurements are only as good as the calibration behind them. Our NATA-accredited calibration laboratory services Hioki analyzers to manufacturer specifications, with calibration certificates traceable to national standards. We understand the compliance requirements for test equipment used in statutory testing and can coordinate calibration schedules that keep your instruments certified without disrupting your work schedule.

Current Sensor Selection Expertise

The PQ3198’s flexibility means choosing the right current sensors for your applications. We help you select from Hioki’s range of clamp sensors (60A to 600A), flexible Rogowski coils (up to 6000A), and AC/DC sensors for mixed current applications. Whether you’re monitoring motor circuits, solar inverters, or building switchboards, we’ll spec the sensor combination that gives you accurate measurements within budget.

Ready-to-Use Kits & Custom Configurations

The PQ3198 is available as the base unit (sensors ordered separately) or complete kits (PQ3198-92 or PQ3198-94) including four current sensors and accessories. Can’t decide? We’ll help you configure the right package for your typical applications – and we keep common sensors in stock for when your work scope expands.

Australian Stock, Fast Delivery

We maintain inventory in Australia, so you’re not waiting weeks for equipment to arrive from overseas. Place your order and have the PQ3198 on your bench within days – ready to deploy on that urgent troubleshooting job or scheduled commissioning work.

Frequently Asked Questions

Can the PQ3198 measure DC current for solar monitoring? Yes – when used with Hioki’s AC/DC current sensors (CT6862, CT6863, or CT6865), the PQ3198 accurately measures DC current with automatic zero compensation. This eliminates the drift issues common with Hall-effect sensors, making it ideal for solar array monitoring or EV charging applications where DC current measurement is required.

How does the PQ3198 compare to the older PQ3100 model? The PQ3198 offers significant improvements: IEC 61000-4-30 Edition 3 Class A compliance (vs. Edition 2 in the PQ3100), extended supraharmonic measurement to 80 kHz (vs. 40 kHz), direct sensor power supply eliminating external AC adapters, and the new PQ ONE software with improved reporting. If you’re working with modern inverter-based systems or require current Class A compliance, the PQ3198 is the right choice.

What’s included with the PQ3198, and what needs to be ordered separately? The base PQ3198 includes the analyzer, voltage cables, AC adapter, battery pack, SD card, carrying strap, USB cable, and PQ ONE software. Current sensors are ordered separately to match your specific applications. Alternatively, the PQ3198-92 kit includes four 600A clamp sensors, or the PQ3198-94 kit includes four 6000A flexible sensors – covering most industrial applications straight out of the box.

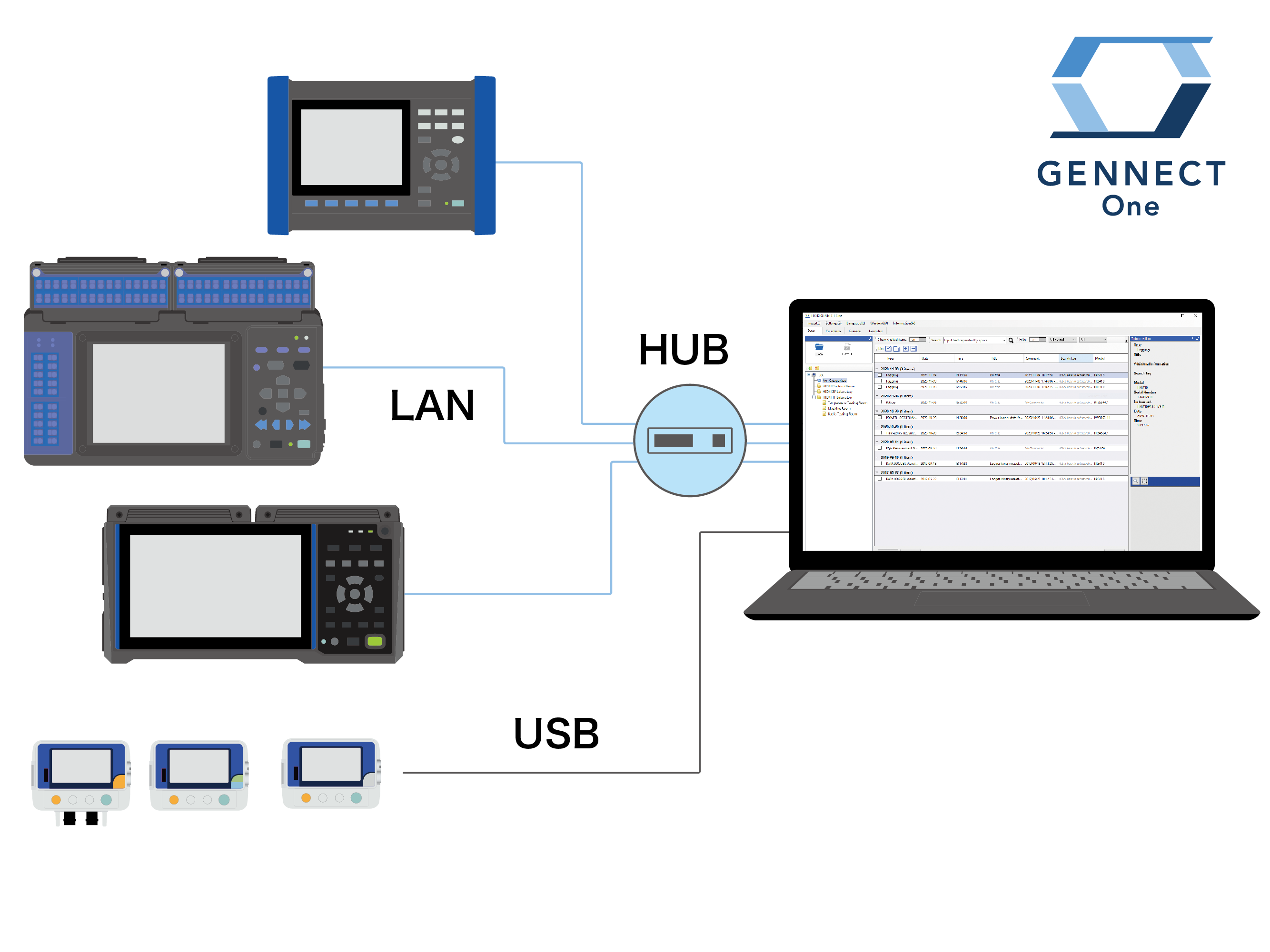

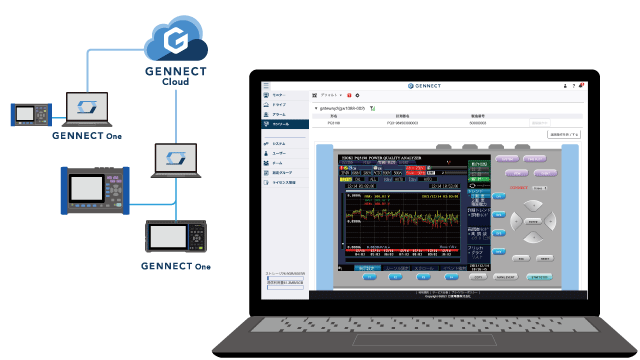

Can I monitor power quality remotely rather than reviewing data after the fact? Yes – the PQ3198 supports remote monitoring via the GENNECT One software over LAN connection. View real-time measurements from your office PC, receive automatic notifications when events occur, and download recorded data without visiting the site. For genuinely remote installations, the GENNECT Cloud service enables access from anywhere with internet connectivity.

Is calibration required, and how often? Like all precision test equipment, regular calibration maintains measurement accuracy. Hioki specifies annual calibration for the PQ3198, and most compliance applications require calibrated instruments with current certification. We provide NATA-accredited calibration services with fast turnaround – typically one week from receipt. We’ll also set up calibration reminders so your equipment never expires when you need it most.

Order Your Hioki PQ3198 Power Quality Analyzer Today

Stop troubleshooting power quality issues without proper data. The Hioki PQ3198 delivers the measurement accuracy, compliance certification, and comprehensive recording capability that Australian electrical contractors and facility maintenance teams depend on.

Ready to discuss your specific application or configure the right analyzer package? Contact Rapid-Tech Equipment – we’ll help you select current sensors, arrange calibration, and get your PQ3198 ready for deployment.

The PQ3198 can measure the secondary side of inverters with a fundamental frequency of 40 to 70 Hz and a carrier frequency of up to 20 kHz.It can also measure the efficiency of DC/3-phase inverters.

The PQ3198 can measure the secondary side of inverters with a fundamental frequency of 40 to 70 Hz and a carrier frequency of up to 20 kHz.It can also measure the efficiency of DC/3-phase inverters. Verify the quality of the input (AC) and output (DC) of an EV rapid charger while simultaneously measuring power and efficiency between input and output.

Verify the quality of the input (AC) and output (DC) of an EV rapid charger while simultaneously measuring power and efficiency between input and output.

Show voltage, current, frequency, harmonics, flicker, and other metrics on the Statistics screen. View the maximum, minimum, and average value for measurement data context.

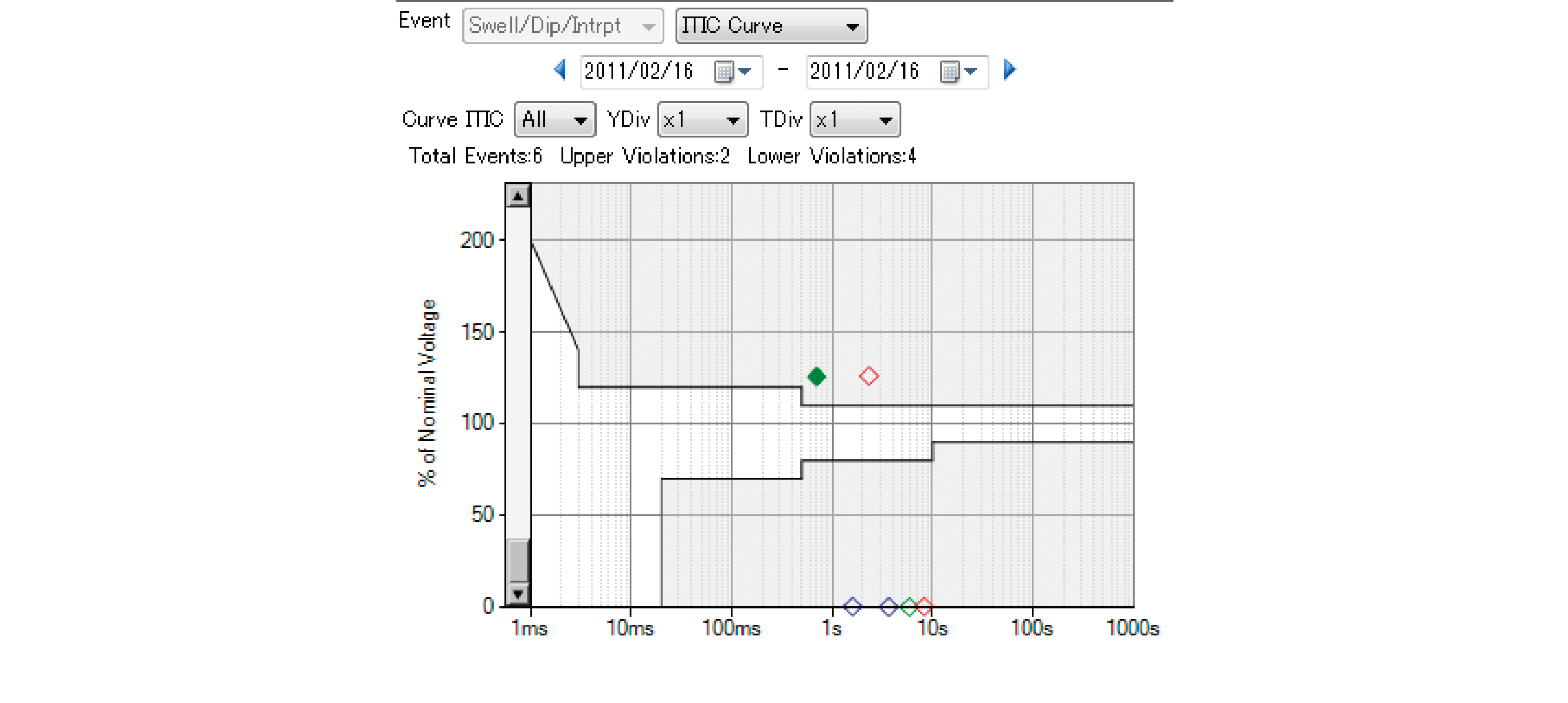

Show voltage, current, frequency, harmonics, flicker, and other metrics on the Statistics screen. View the maximum, minimum, and average value for measurement data context. Automatically generate ITIC curve from recorded event. The curve estimates IT equipment’s resistance to power quality issues such voltage fluctuations.

Automatically generate ITIC curve from recorded event. The curve estimates IT equipment’s resistance to power quality issues such voltage fluctuations.

Reviews

There are no reviews yet.